We Have 18+ Years Industrial Experiences

With over 18 years of experience in die and mould manufacturing, Explore Industries has evolved into a trusted name in the plastic component industry. We specialize in high-precision injection moulding and toolroom services, serving both the luggage and automotive sectors. Our commitment to innovation, integrity and quality has driven our growth from a small toolroom to a 10,500 sq.ft. production facility equipped with advanced moulding machines.

26530

Project Complate

15

Win Gold Awards

Vision & Mission

Our Vision

To produce high-quality products at the lowest cost and become a benchmark in the luggage component industry through innovation and reliability.

Our Mission

To deliver on-time, high-performance plastic components with a customer-first mindset — ensuring quality, efficiency and long-term value.

Shop Floor Machines

Injection Moulding Machine – Make: Electronica

250 TON

- Quantity: 1 units

- Screw Dia: 35 mm

- Shot Weight: 70 g

- Tie Bar Distance: 320 x 320 mm

200 TON

- Quantity: 1 units

- Screw Dia: 55 mm

- Shot Weight: 456 g

- Tie Bar Distance: 510 x 510 mm

- Make: ELECTRONICA

140 TON

- Quantity: 1 units

- Screw Dia: 35 mm

- Shot Weight: 70 g

- Tie Bar Distance: 320 x 320 mm

140 TON

- Quantity: 1 unit

- Screw Dia: 60 mm

- Shot Weight: 609 g

- Tie Bar Distance: 570 x 570 mm

- Make: ELECTRONICA

110 TON

- Quantity: 1 units

- Screw Dia: 55 mm

- Shot Weight: 456 g

- Tie Bar Distance: 510 x 510 mm

- Make: ELECTRONICA

110 TON

- Quantity: 1 units

- Screw Dia: 65 mm

- Shot Weight: 509 g

- Tie Bar Distance: 510 x 510 mm

- Make: ELECTRONICA

Tool Room Machines

VMC HASH

- Quantity: 1 unit

- Table Size: 800 x 500 mm

- Spindle Speed: 8000 RPM

- Controller: Fanuc

VMC BFW

- Quantity: 1 unit

- Table Size: 1000 x 500 mm

- Spindle Speed: 10000 RPM

- Controller: Siemens

Electronica Wire Cut

- Quantity: 1 unit

- Table Size: 400 x 300 mm

- Cutting Taper: ±30°

- Controller: Electronica

Electronica EDM

- Quantity: 1 unit

- Table Size: 400 x 250 mm

- Max Electrode Weight: 50 kg

- Controller: Electronica

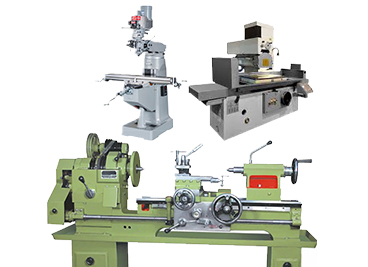

Conventional Machines

- Milling Machine

- Surface Grinding Machine

- Leth Machine

What We Stand For

Innovation

We constantly adapt and upgrade our processes to lead with new thinking.

Teamwork

We believe great results come from collaboration and shared goals.

Safety

We prioritize safe working conditions and long-lasting product safety.

Integrity

We conduct every operation with honesty, fairness and respect.

“Precision, Integrity and Innovation – the pillars on which we build every product.”

At Explore Industries, we don't just manufacture components — we deliver confidence in every part we produce.